FDNY's "Steam Age" Rules Are Breaking NYC's Climate Goals

Century-old refrigerant regulations incentivize owners, developers, and large tenants to choose leak-prone VRF systems, which all but guarantee the atmospheric release of super-polluting refrigerants.

This post draws from an interview with Ben Galuza, a building performance expert with deep knowledge of building mechanical systems and their interactions with energy systems. Ben has led engineering teams at Google, Rivian, and Turner Construction Company. The Ideas expressed in this post are Ben's and mine only.

(Ron Kleemann, Soho Saint (Fire Engine), 1976)1

New York City's building operators face an artificial choice: install efficient centralized heating and cooling systems that require expensive round-the-clock operators, or deploy distributed VRF systems that will inevitably leak their entire refrigerant charge into the atmosphere. The Fire Department's antiquated refrigerant regulations, designed for steam boilers from the 1920s, are undermining the city's climate ambitions while adding millions to development costs.

Key Points

The Fire Department of New York (FDNY)'s operator requirements compel developers to opt for leak-prone VRF systems over efficient centralized plants, thereby guaranteeing refrigerant emissions with global warming potentials (GWPs) ranging from 675 (R32) to 2,088 (R410a) times that of CO2 (GWP of 1).

The regulations stem from century-old steam safety concerns but now apply to modern closed-loop refrigeration systems, which have fundamentally different risk profiles and automated monitoring capabilities.

Eliminating operator requirements could unlock efficiency gains of 50-100% through centralized heat pump plants, while reducing total project costs by avoiding FDNY Q-01 operator Certificate of Fitness labor requirements.

Performance-based safety systems, equipped with automated monitoring and integration with the fire department, can maintain safety while enabling innovation in building electrification and efficiency.

Welcome to Range NYC. If this is your first time here, consider starting with 'A Note on Content,' which outlines the intentions behind this publication. You can also read through the About page to learn more.

Range NYC publishes occasional thought pieces on real estate development and construction management in New York City. The posts are long-format and dive into specific issues often covered in a series. Topics may relate to policy, technical details of project execution, or deal analyses. Any insights are derived from lived experience.

The Steam Age Problem in the Electric Era

The FDNY's refrigerant operator requirements emerged from legitimate safety concerns, stemming from the explosive nature of refrigerants from the past century and their high propensity for leaks. The solution that the Fire Department of New York (FDNY) adopted—a Refrigerating System Operating Engineer (RSOE)—to address this risk was borrowed from high-pressure steam systems operators, who typically worked with pressures exceeding 15 PSI in the early 1900s. Steam systems posed an explosion risk and still do today, when valves fail or condensate accumulates, requiring skilled operators to manually monitor pressure gauges and safely shut down systems before catastrophic failures occur. These regulations made perfect sense when Willis Carrier2 introduced air conditioning to the mass market, and as steam engineers were manually managing boiler pressures, they now had an additional complex system to manage and operate.

Today's Q-01 operating engineer requirement kicks in at seemingly arbitrary thresholds: 50 horsepower for Group A1 refrigerants, such as R-410A, or 200 pounds of refrigerant for mildly flammable A2L refrigerants, like R-32.3 These cutoffs force system designers into elaborate workarounds to stay below limits that have no relationship to actual safety risks in modern buildings.

(Summary table of the top 10 most common refrigerants used in HVAC technologies. Refrigerants work by absorbing and releasing heat as they change between liquid and gas states. This happens in a continuous cycle with four main components: (1) Compressor, (2) Condenser (Outside Coil), (3) Expansion Valve, (4) Evaporator (Inside Coil).)4

Modern refrigeration machine systems operate as closed loops with fundamentally different risk profiles than the open steam systems that inspired these regulations. While refrigerants can be flammable or toxic if released, today's A1 refrigerants, such as R 1234ze, have low toxicity and no flammability at ambient temperatures. In contrast, newer A2L refrigerants, such as R-32, are only mildly flammable and have low toxicity. More importantly, building codes already require exhaust systems, leak detection, and emergency shutoffs for refrigeration equipment in every part of the country.

The disconnect becomes absurd when you realize that New York's regulation of modern refrigeration machines attempts to mirror early 1900s steam boiler regulations for a 2024 heat pump or chiller, which can feature redundant sensors, automated controls, and integration with an automated and computerized building management system. It's like requiring a telegraph operator for every smartphone because both use electricity. Even more absurd, New York City is the only municipality with this requirement for commercial applications.

The VRF Workaround Creates a Climate Disaster

Developers have responded to the FDNY's operator requirements by deploying Variable Refrigerant Flow (VRF) systems that stay below the horsepower and refrigerant volume thresholds. Each VRF outdoor unit operates independently with smaller refrigerant charges, technically avoiding the need for full-time operators while serving the same building loads.

This regulatory arbitrage comes with devastating environmental consequences. Industry research from CIBSE suggests using an annual leakage rate of 6% for VRF systems and an end-of-life recovery rate of 97%. Research also shows that among more than 4,000 residential air conditioners in California, approximately 62% of the systems were undercharged.5 VRF systems multiply this problem by distributing refrigerant throughout buildings in hundreds of separate loops, each vulnerable to leaks from installation errors, vibration, or component failures.

When a centralized chiller loses its refrigerant charge, you're dealing with one single release and point of failure - in a ventilated machine room. When VRF systems fail, you're looking at dozens of smaller releases across multiple systems over time—death by a thousand cuts. The refrigerants used in these systems have global warming potentials ranging from R-410A, which is 2,088 times that of CO2, to newer R-32, at 675 times that of CO2, meaning even small leaks create outsized climate impacts.4 years).

The cruel irony is that New York's attempt to manage refrigerant safety through operator requirements has created a system guaranteed to release more refrigerants into the atmosphere than any alternative approach. As Project Drawdown research indicates, refrigerant management is among the highest-potential impact solutions for reducing global carbon emissions.6

To be clear, there are contemporary systems that require specialized and trained operational personnel, and these systems pose real risks that necessitate monitoring and maintenance by skilled personnel. Industrial and process plant applications, central district energy plants, campus energy plants, and certain mega-projects with centralized plant operations can benefit from skilled operating labor, where the statistical risk, data, refrigerant type, and charge should guide any regulations imposed. The point that this article is making is not that these positions should go away but rather that our code needs to be adapted to match the technologies we have available today and upskilling the operating engineers to be engaged in meaningful work where their skillsets and training can be focused rather than monitoring systems that no longer require monitoring.

(Infographic of potential common replacement refrigerants to R410A and their GWP)7

The Economics of Regulatory Inefficiency

The financial impact of operator requirements extends far beyond salary costs. A licensed Q-01 operating engineer in New York costs $150,000 - $200,000 annually, including benefits,8 but the real cost arises from the constraint this creates on system design. Projects that could achieve 50-100% efficiency improvements through centralized heat pump plants with thermal storage become financially unviable when $2-4 million in operator costs is added over 20 years.

The direct hit to net operating income (NOI) for the additional personnel cost alone, not accounting for efficiency gains and reduced electrical energy costs from the higher coefficient of performance (COP), since in centralized systems, at the current 6% cap rate for multifamily assets in NYC, erases nearly $ 3 million in project value. We need to start asking when these tradeoffs make sense. For every regulatory action that affects building codes, it either makes development of much-needed real assets more or less likely to proceed. And in a time when the city is focused on producing more housing that New Yorkers can afford, we would do well to review our building codes with a value creation alignment to unlock projects that would otherwise not get built in New York City.

Consider a typical large multifamily residential building with several hundred apartments. The building could deploy an air-source heat pump plant on the roof, circulating tempered water to fan coil units throughout the building. This approach would centralize all refrigerant outdoors, enable heat recovery between zones, and achieve coefficient of performance ratings of 5-6, compared to 2.5-3 for distributed VRF systems. The efficiency gains could reduce peak electrical demand by 30-40%, lowering infrastructure costs for both the building and the grid.

Instead, developers opt for distributed systems that eliminate operator requirements but incur higher energy costs, increased maintenance complexity, and environmental damage from refrigerant leaks. The regulatory tail is wagging the technological dog, forcing suboptimal outcomes that satisfy bureaucratic requirements while failing actual performance objectives.

Building owners who take long-term views understand that centralized systems offer superior reliability, easier maintenance access, and lower lifecycle costs. But the upfront operator requirement makes these systems pencil out only for institutional owners willing to absorb immediate costs for long-term benefits.

Performance-Based Solutions for Modern Systems

Every other major city manages refrigeration safety without requiring full-time operators for systems that would trigger FDNY requirements. International building codes already mandate refrigerant leak detection, emergency ventilation, and automatic shutoffs for these refrigeration machinery rooms.9 These performance-based approaches achieve safety objectives through instrumentation controls rather than human oversight.

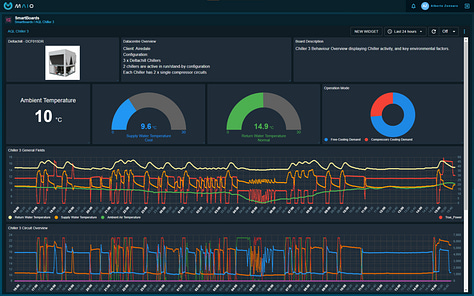

New York could implement similar performance standards while maintaining enhanced safety requirements that reflect the city's density and complexity. Fire department integration with building management systems could provide real-time monitoring of all mechanical equipment, automatic emergency response for any detected leaks, and redundant safety systems that exceed current standards.

Today, technology enables the creation of monitoring systems that surpass the capabilities of any human operator. Wireless sensors can detect refrigerant concentrations at parts-per-million levels, automated valves can isolate systems faster than human response times, and building management systems can coordinate emergency responses across multiple safety systems simultaneously.

Consider how elevator safety evolved from requiring operators to automated systems with multiple redundant safety mechanisms. Modern elevators are dramatically safer than their manually operated predecessors, despite carrying millions of passengers daily without human operators. And when you step into an elevator, you immediately know when it was last inspected and when the next inspection is due. The same progression could apply to refrigeration systems, provided they meet appropriate performance standards.

Unlocking Innovation Through Regulatory Reform

Eliminating the Fire Department of New York (FDNY)'s operator requirements wouldn't just reduce costs—it would unleash innovation in building electrification and efficiency. Developers could explore ambient temperature loops connecting multiple buildings, thermal storage systems that shift electrical loads off peak hours, and heat recovery systems that capture waste heat from data centers or other sources. Many states are now piloting Utility Thermal Energy Networks, linking them to Job Creation, as New York State has done; however, NYC’s RSOE regulations create an additional barrier to implementation that other cities and states will not encounter, putting NYC at a step behind in this emerging framework. Massachusetts for example is allowing Gas Companies to participate in the development of thermal energy networks through a slate of new legislation.10

The regulatory clarity would also accelerate the adoption of next-generation refrigerants with lower global warming potential. Natural refrigerants, such as CO2 and ammonia, which European manufacturers are increasingly deploying, could become viable in New York if developers weren't constrained by arbitrary horsepower and refrigerant weight thresholds designed to mirror the steam boiler industry of the previous century. Even the transition to A2L refrigerants, such as R-32, with a 70% lower global warming potential than R-410A, becomes complicated when the 200-pound threshold forces system fragmentation.11

District-scale thermal networks become feasible when individual buildings can connect to ambient loops without triggering operator requirements. Imagine a system connecting buildings around Hudson Yards or the World Trade Center through underground thermal loops, with each building operating heat pumps that extract or reject heat as needed. The efficiency gains and grid resilience benefits could be transformational. While other states and cities can lean into these emerging trends, NYC is in danger of being left behind and may need to sprint to catch up.

New York's market size gives it a California-like influence over the national HVAC manufacturing industry. Regulatory reform here could drive innovation that benefits building performance nationwide, rather than forcing manufacturers to design around one city's peculiar requirements.

The Path Forward: Performance Over Process

The FDNY's refrigerant regulations exemplify the kind of legacy thinking that hinders cities from efficiently achieving their climate goals. Like many safety regulations, they emerged from real historical problems but have calcified into bureaucratic requirements that no longer serve their original purpose.12

The solution isn't eliminating safety oversight—it's updating safety standards to reflect modern technology and performance capabilities. Performance-based regulations that specify desired safety outcomes while allowing flexibility in achieving them would maintain New York's safety leadership while enabling the innovation necessary to meet climate commitments.

Cities worldwide are grappling with the challenges of building electrification as they phase out fossil fuels. New York has an opportunity to lead by demonstrating that safety and efficiency aren't opposing forces—they're complementary objectives that modern technology can achieve simultaneously.

The question isn't whether New York will eventually update these regulations, but whether it will do so proactively to capture first-mover advantages or reactively after other cities have seized the innovation opportunities.

Ever upward.

*This Substack is a work in progress that will endeavor to improve over time. If you're reading this, thank you for making it to the end of the post — you're part of the community that can help improve this content. Please comment, share, and send feedback that can improve future posts. What was left out of the above? How could the argument be taken further? Was the post true to Range NYC’s stated objectives as outlined in 'A Note on Content'? Send a message with your thoughts.

Ron Kleemann: A major artist of the photorealist movement, Ron Kleemann is known for his meticulous paintings of race cars, trucks, airplanes, and other objects he viewed as American icons. Beginning his career as a sculptor, Kleemann turned to painting in the late 1960s, after becoming frustrated with the limited space available in New York City. He produced images of cars and logos that convey a Pop Art sensibility, as well as his love of form and surface. Working directly from photographs, Kleemann was interested in images that capture reflections and dynamic angles, suggesting the potential for movement. He cited his Midwestern upbringing as the source of his love of cars. “I simply paint what I see, and what appeals to me,” Kleemann said, “I like the display of things: signs, labels, colors, and compositions are all very important to me.”

https://en.wikipedia.org/wiki/Willis_Carrier

NYC Fire Department. "Certificate of Qualification for Refrigerating System Operating Engineer (Q-01)" and "Refrigerating System Permit." NYC.gov, accessed 2025

https://www.geoclima.com/an-overview-of-refrigerants-the-choices-for-the-future/

Detailed basic explanation of the refrigerant cycle: Link to YouTube

CIBSE Technical Memorandum 65. "Refrigerant leakage scenarios for different refrigerant-based systems," 2021; ScienceDirect. "Leakage, diffusion and distribution characteristics of refrigerant in a limited space," 2023.

Project Drawdown. "Refrigerant Management." March 2024.

Courtesy of Handel Architects: https://handelarchitects.com/firm/insight/new-refrigerants-will-complicate-vrf-system-design

Industry compensation data from Operating Engineers Local 30 and NYC labor market analysis.

NYC Fire Code Section 606.1.1 "Supervision" and International Building Code provisions for refrigeration equipment safety.

EPA Global Warming Potential Reference Table and Refrigerant Classification Standards.

Yale Sustainability. "Yale Undergrad Confronts a Hidden Climate Threat: Refrigerant Leaks," accessed 2025.

Can a building super also wear the hat of an operating engineer? If so, does this negate the additional overhead cost?