Cross-Training and Simplicity Beat Scale in Manufacturing

Euro Cabinets increased output by removing equipment and cross-training 12 workers to handle any task in their 25,000 sq ft facility.

This article reviews how Euro Cabinets transformed their manufacturing operation by counterintuitively reducing equipment and staff while increasing output. The article below is on an interview with Simcha Itzkowitz, the second-generation owner and operator of Euro Cabinets. Simcha’s approach to management and manufacturing offers insights for the production of real assets at all scales.1

(Tony Delap, Hands and Stick, 1991)2

Key Points

Cross-functional training eliminates bottlenecks: When every employee can operate every machine, production never stops due to absenteeism or specialization gaps.

Material-driven scheduling outperforms demand-driven scheduling: initiating production when all materials are available, rather than when customers request delivery, minimizes risk and creates buffer time.

Removing equipment increased productivity: Fewer machines meant fewer idle workers and less finger-pointing when deadlines weren’t met.

Local manufacturing provides speed advantage: Custom corrections and rush orders can be completed in days, not months like overseas alternatives.

Lean overhead structure scales efficiently: Running 25,000 square feet with 12 employees while maintaining quality demonstrates the power of operational discipline.

Welcome to Range NYC. If this is your first time here, consider starting with ‘A Note on Content,’ which outlines the intentions behind this publication. You can also read through the About page to learn more.

Range NYC publishes occasional thought pieces on real estate development and construction management in New York City. The posts are long-format and dive into specific issues often covered in a series. Topics may relate to policy, technical details of project execution, or deal analyses. Any insights are derived from lived experience.

The Counter-Intuitive Path to Higher Output

Simcha Itzkowitz of Euro Cabinets discovered something that defies conventional manufacturing wisdom: removing equipment from his production floor actually increased productivity. The Brooklyn-based cabinet manufacturer learned this lesson the hard way after visiting his New Jersey facility and consistently finding jobs behind schedule.

“I used to come to the factory and see people waiting for a job to be finished,” Itzkowitz explains. “When I asked why jobs weren’t done, it was always ‘he didn’t do this’ or ‘he didn’t do that.’ That told me we had too many ‘he’s’ in the factory.” The solution wasn’t adding more equipment or workers—it was eliminating excess capacity that created inefficiency.

The breakthrough came from recognizing that cabinet manufacturing doesn’t require full-time specialists at each station. A skilled operator needs perhaps one hour per day on the panel saw, regardless of daily output volume. Having dedicated operators sitting idle for the remaining seven hours created costly downtime and shifted accountability. By reducing equipment and cross-training all employees, Euro Cabinets eliminated these inefficiencies.

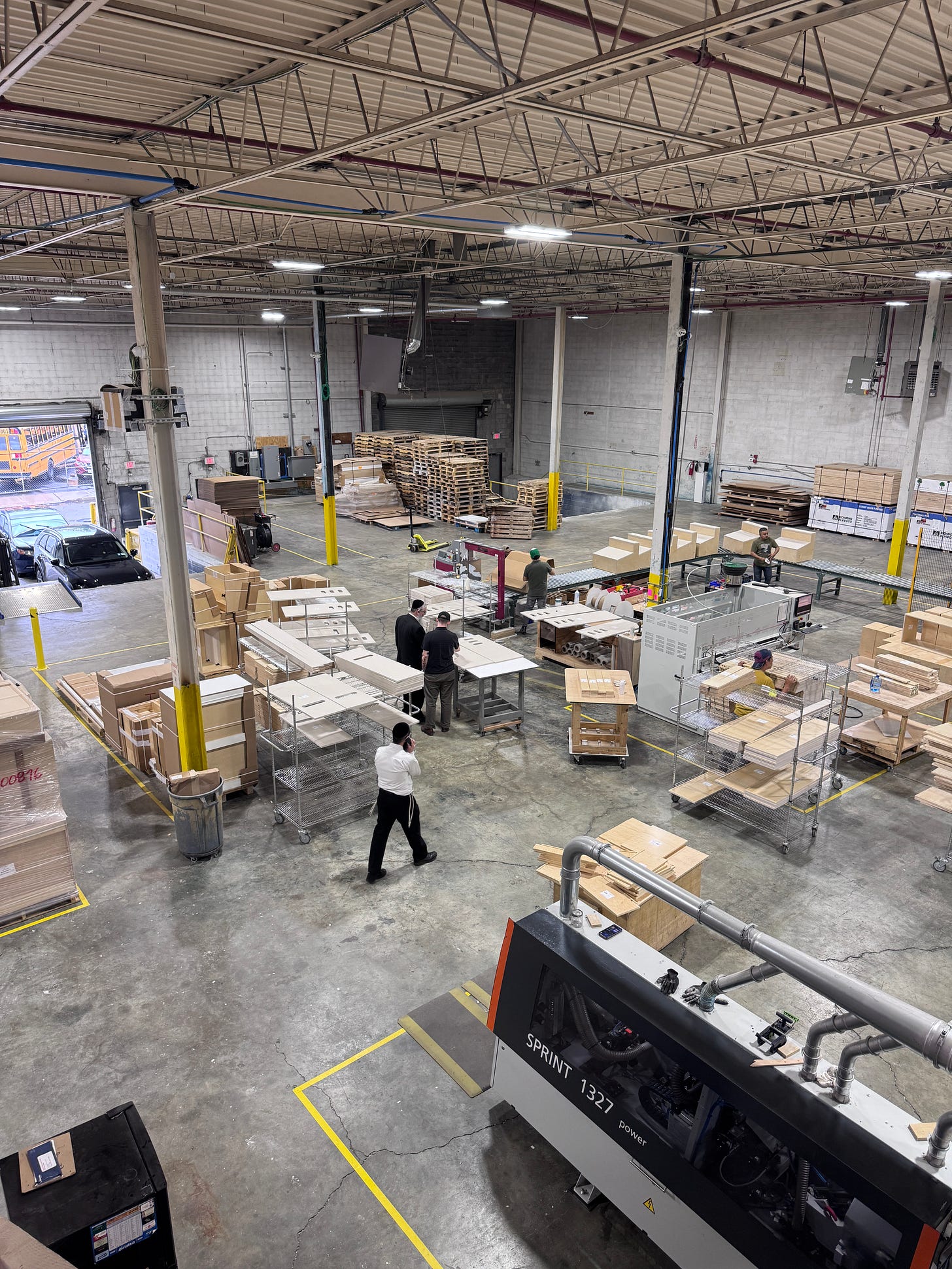

(Photograph from Euro Cabinet’s assembly facility, depicting the final stages of an order for the labor and delivery department of a hospital in the New York metropolitan area.) The facility is laid out in a square ‘line’, anchored by an elevated management office in the middle of the production ‘line’ rather than in linear production lines.)

Cross-Training as a Manufacturing Strategy

Euro Cabinets operates with radical simplicity: one production line, 12x employees, and every worker trained on every function. This cross-functional approach means production never stops due to absenteeism or bottlenecks at specialized stations. When the edge-banding operator doesn’t show up, another team member immediately steps in without disrupting the schedule.

The key enabler is extensive pre-planning through digital systems. Every cabinet project gets programmed using Mosaic CNC software before production begins. Itzkowitz personally reviews every cut sheet to ensure accuracy. Once programmed correctly, the manufacturing process becomes like assembling a puzzle—if pieces don’t fit, there’s a programming error, not a production issue. The team always runs a test fit, taking each representative fabrication detail from start to finish and iterating on any kinks before starting production of a full order.

This approach eliminates the costly custom problem-solving that plagues many manufacturers. Instead of having specialized workers figure out complex assemblies on the fly, Euro Cabinets ensures all complexity gets resolved during the programming phase. The result: any trained employee can handle any part of the production process.

(An Omal Insert 1300 drilling, gluing, and doweling machine representing one of several stations within the production line.)3

Material-Driven Production Scheduling

Euro Cabinets schedules production based on material availability, not customer demand dates. This seemingly backwards approach actually reduces risk and improves delivery reliability. When all materials for a project arrive, production begins immediately - regardless of the requested delivery date.

“I make the demand based on the material, not based on when the customer needs it,” Itzkowitz explains. This strategy provides crucial buffer time for unexpected issues while maintaining predictable lead times. The company tracks productivity using a simple metric: sheets of material processed per day, averaging 45 sheets with peaks of 55. Maintaining a steady state of production without downtime is key to the economics of profitably running a manufacturing operation. This core metric of sheets per day is the North Star for Itkowitz. He knows the input costs, revenue potential, and profit margins on a per sheet basis for his business and is laser-focused on maintaining steady, high-efficiency throughput.

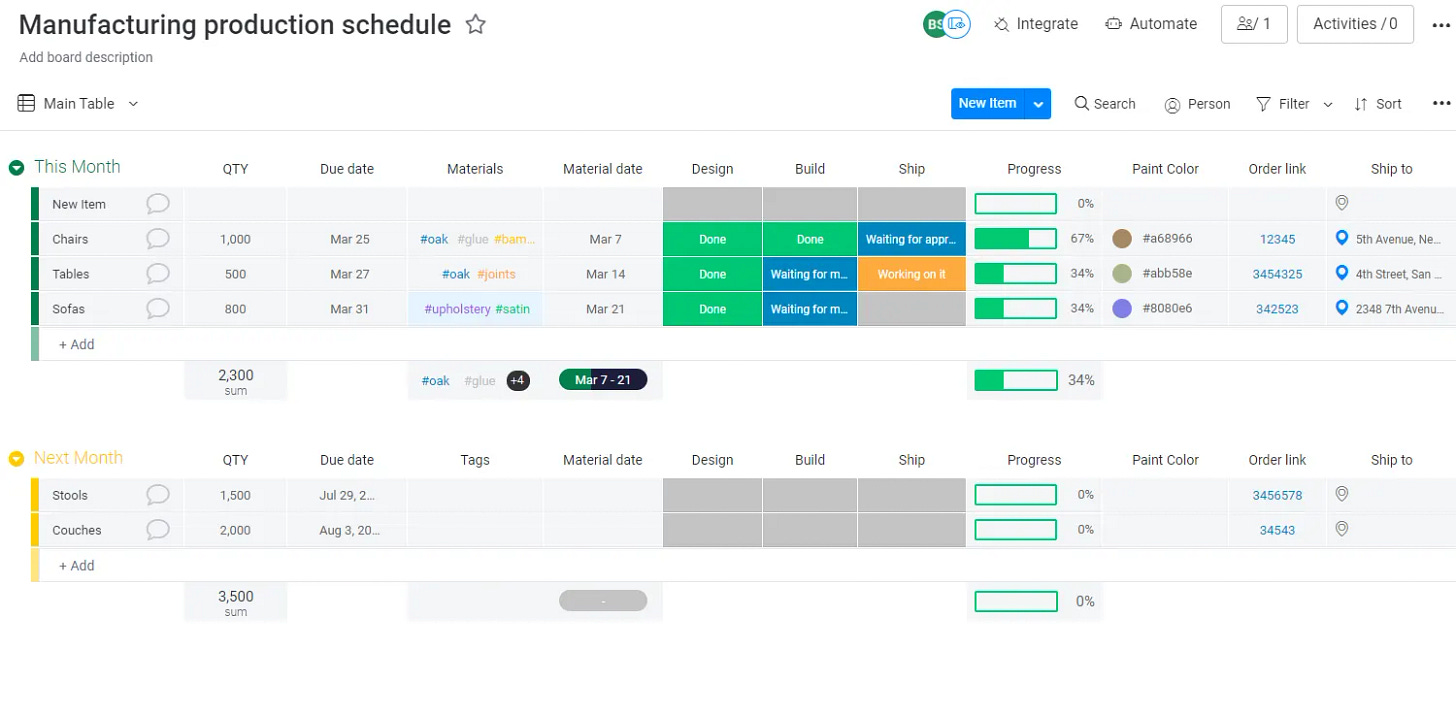

The scheduling system operates transparently through Monday.com, essentially a sophisticated spreadsheet that shows every employee the production queue, material status, and deadlines. Workers can see exactly what needs to be cut, assembled, or finished without waiting for management direction. This visibility eliminates the excuse of “I didn’t know what to work on next."

(Example image of a Monday.com production scheduling dashboard. The point is not the specific tool but rather that all team members have access to the same single-source of truth baseline information on production capacity and upcoming tasks, which empowers the agency across the team to pick up the next task as soon as possible.)

Running the manufacturing facility on a per sheet metric based on material-driven scheduling is successful, again counterintuitively, because Itkowitz never works overtime and only works four days a week. The team maintains high cost efficiency by running on a 4x10 schedule (Monday through Thursday, 10 hours per day) and never pays or runs overtime. This means the ratio of non-productive time to productive time within a shift is lower, which directly impacts the bottom line in terms of production efficiency. To illustrate, a 1-hour lunch break over an 8-hour shift results in a 12.5% efficiency loss, whereas a 1-hour lunch break over a 10-hour shift yields a 10.0% efficiency loss. That 2.5% delta doesn’t seem like a lot when you look at it at a high level, but when reframed as 25% of the efficiency loss over a 10-hour shift, it becomes significant.

Not working overtime creates a culture of ownership on the manufacturing floor where the team understands and is incentived to work efficiently to complete processes within the alloted production time for an order rather than developing the psychology of being able to finish on OT which is also paid at a higher rate and creates a an unproductive incentive to put things off until they are on over time.

The Economics of Lean Manufacturing

Euro Cabinets proves that smaller can be more profitable. Operating from 25,000 square feet with 12 production employees, the company processes approximately 9,000 sheets annually while maintaining competitive pricing and superior delivery times. The payroll runs roughly $40,000 per month for production staff working four 10-hour days.

The lean approach extends beyond staffing to equipment and overhead. Rather than owning delivery trucks, the company outsources shipping on a per-job basis, avoiding insurance, maintenance, and idle capacity costs. Office equipment stays minimal—no leased copiers or unnecessary technology. “You need a computer and a telephone. That’s all you need,” Itzkowitz notes.

This operational discipline allows Euro Cabinets to compete effectively against both overseas manufacturers and larger domestic competitors. When projects require corrections or rush deliveries, local proximity becomes a decisive advantage. While overseas suppliers might take four to five months to correct a mistake, Euro Cabinets can remake components in days.

Lessons for NYC Development

For NYC developers and contractors, Euro Cabinets demonstrates the value of local manufacturing partnerships that prioritize operational efficiency over scale. The company’s approach offers several insights applicable to construction project management:

First, transparency and accountability systems reduce delays more effectively than additional resources. When every team member can see project status and requirements, coordination improves naturally. Second, building buffer time through early action (starting when materials arrive) proves more reliable than aggressive scheduling. Third, cross-training and operational flexibility often deliver better results than specialized efficiency.

The 4-day, 10-hour work schedule also provides interesting lessons for construction scheduling. Concentrated work periods with no overtime create predictable labor costs while maintaining high productivity. Workers know they must complete tasks within fixed hours, thereby eliminating the inefficiency that often accompanies open-ended schedules.

The Future of Local Manufacturing

Euro Cabinets represents a model for competitive local manufacturing in high-cost markets like NYC. By focusing on operational excellence rather than scale, the company maintains profitability while offering speed and flexibility advantages over large competitors.

This approach becomes increasingly valuable as supply chain disruptions highlight the risks of overseas dependencies. Local manufacturers who can deliver quality products with short lead times provide crucial project risk mitigation for developers. The premium for local production often pays for itself through faster project completion and reduced carrying costs.

The key insight is that manufacturing competitiveness doesn’t require the largest facility or most equipment—it requires the most efficient operation. Euro Cabinets proves that disciplined execution, transparent systems, and cross-functional teams can create sustainable competitive advantages even in expensive markets.

Manufacturing Excellence Through Simplicity

Euro Cabinets’ success demonstrates that manufacturing efficiency comes from eliminating waste and complexity, not adding capacity. By reducing equipment, cross-training workers, and scheduling based on material availability rather than demand, the company achieved higher productivity with lower overhead. For NYC's development community, these lessons highlight the value of local manufacturing partners who prioritize operational discipline over scale. In an industry often focused on adding resources to solve problems, Euro Cabinets proves that subtracting inefficiency can be more powerful than adding capacity.

Ever upward.

*This Substack is a work in progress that will endeavor to improve over time. If you're reading this, thank you for making it to the end of the post — you're part of the community that can help improve this content. Please comment, share, and send feedback that can improve future posts. What was left out of the above? How could the argument be taken further? Was the post true to Range NYC’s stated objectives as outlined in 'A Note on Content'? Send a message with your thoughts.

Interview with Simcha Itzkowitz, Euro Cabinets, June 18, 2025

Tony DeLap, a pioneer of West Coast Minimalism and Op Art, has spent more than half a century producing meticulously crafted, illusionistic abstract sculptures that challenge perception with their teasing, shifting shapes, form, and sense of depth. Associated with the L.A.-based Finish Fetish movement of the 1960s, DeLap has mentored such prominent artists as Bruce Nauman and James Turrell. Staying true to Minimalism decades after the height of its popularity, he defines the work of art as “a thing in itself.” Eschewing outside references, DeLap strips art to its essence: materials and form. These materials include wood, metal, and plastics, formed into geometric shapes and multipart structures filled with illusions of depth and formal relationships that are both playful and rigorous. DeLap’s work was included in “Primary Structures” (1966) and “American Sculpture of the Sixties” (1967), two exhibitions that helped to define Minimalism.

Omal Machine Systems: https://www.omal.eu/5-drilling-and-dowel-insertion/39-insert1300-2500

Fascinating article! This success story turns the historical wisdom about hyper-specialization and JIT production on its head. Succinctly and elegantly written, nice work!